MANUFACTURING TECHNOLOGY

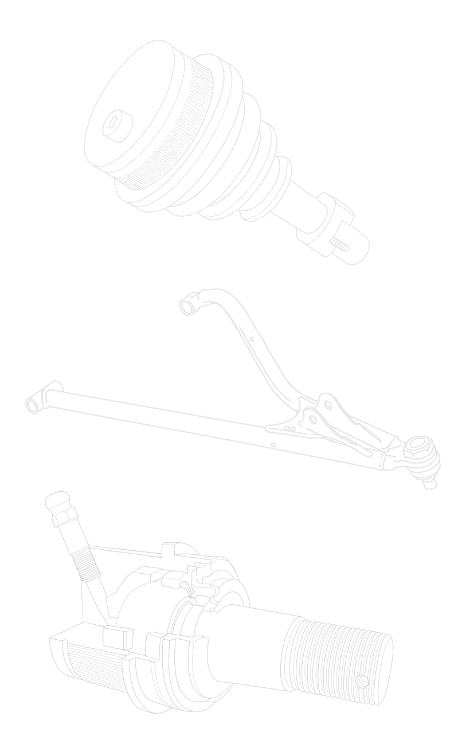

In the off-road aftermarket world, performance, durability, and consistency are non-negotiable.

That's why we go beyond just producing parts—we build systems that ensure every chassis component we manufacture meets the demands of the most extreme terrain.

At Motorpro, we take pride in showcasing our robust and dependable manufacturing capabilities to our valued customers. With over 30 years of experience in chassis component production, we are steadfast in our commitment to delivering quality and efficient output.

Our advanced production technologies and intelligent management systems work together to ensure that our manufacturing process meets the highest standards. We deliver custom suspension and steering components that are built to spec, on time, and ready for the trails of North America, Australia, and the Middle East.

PROCESS OVERVIEW

CONSULTATION

SURFACE FINISHING

SHIPMENT

MACHINING CAPABILITIES

We maintain full in-house machining capabilities to ensure control over every detail:

- Turning: Threading, shafts, shoulders, precision diameter work

- Milling: Slotting, facing, angled cuts, and high-precision drilling

- Heat Treatment: Induction or full part hardening for wear resistance

- Surface Finishing: Zinc-nickel plating, powder coating, anodizing

- Quality Inspection: Inbound, in-process, and final QC + functionality testing

SMART PRODUCTION MANAGEMENT

We integrate digital tools and real-time data to boost productivity, reduce errors, and ensure traceability:

- ERP Integration: Connects order tracking, inventory, scheduling, and BOM management

- Real-Time Line Monitoring: Equipment status, cycle time, and downtime alerts at a glance.

- Digital SOP System: On-screen work instructions with key tolerances and images per station

- Tooling & Fixture Management: Track usage, maintenance, and part matching to prevent mismatch

- Continuous Improvement: Quality data looped back into process and design optimization