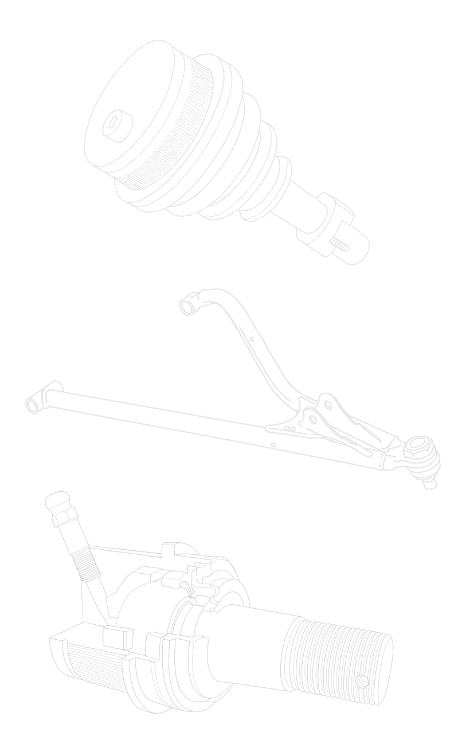

Ball Joint

Motorpro’s ball joint ensures precise steering, enhances suspension stability, and improves vehicle handling. It reduces wear, increases durability, and minimizes maintenance costs, providing a smoother, safer ride in diverse conditions.

Description

A ball joint is a pivotal suspension component in a car, connecting the control arm to the steering knuckle. It allows smooth, multi-directional movement for steering and suspension, ensuring precise handling, stability, and comfort while absorbing shocks on various road conditions.

As one of the leading ball joint manufacturers in Taiwan, Motorpro delivers high-performance custom ball joints designed for OEMs, aftermarket brands, and distributors. Featuring forged housings and wear-resistant designs, our ball joints excel in high-angle, long-travel setups. We offer upper and lower ball joints in press-in and bolt-on types, with customizable offset designs to meet specific requirements.

Motorpro supports sample-based prototyping and low-volume production, ensuring flexibility for your manufacturing needs. Backed by advanced in-house testing for durability and performance, our ball joints are engineered for reliability in demanding applications. Partner with Motorpro for superior quality, technical expertise, and scalable production solutions tailored to your brand’s specifications. Please do not hesitate to contact us for further details.

Features

- Hardened Ball Stud 4140 Chromoly

- Premium Oversized Forged Housing

- Greaseable Joint Design

- High-swing-angle

- Sealed Boots

- Improved Strength and Rigidity over OEM

FAQs

Greaseable Ball Joints – serviceable, ideal for off-road.

High-Angle Ball Joints – greater articulation for lifted vehicles.

Metal-on-metal bearing Designs – durable for extremely heavy-duty use.